GPAK Grid Type Structured Packings Portfolio

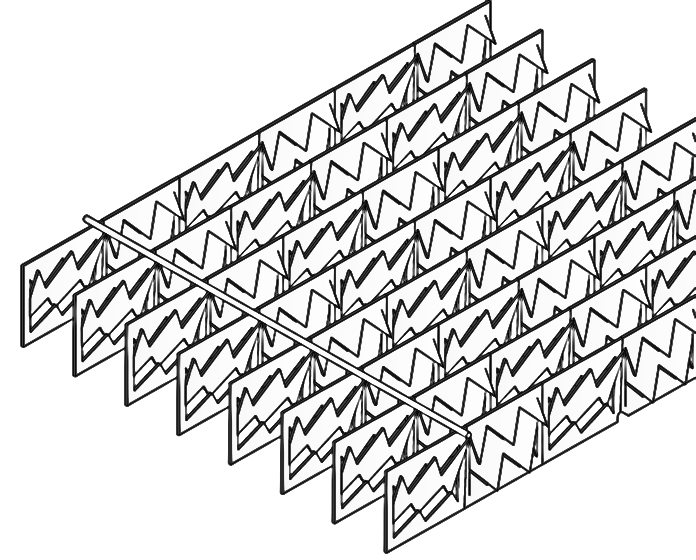

GPAK #2

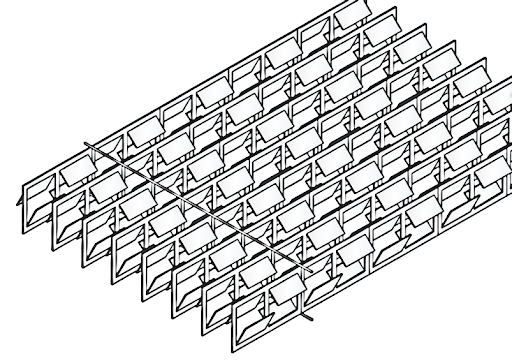

GPAK #3

GPAK grid packing is constructed from stamped metal blades at angles connected with metal rods to provide a rigid structured and high open area. The configuration with sloped blades results in washing of the packing surface by down flowing liquid. The wide spacing of blades allow easy passage of sloid particles. This couple with no horizontal surface, GPAK allows easy drainage of liquid with no accumulation of solid and or liquid with minimum liquid hold-up leading to excellent fouling and or coking resistance.

Typical thickness for GPAK is 1.5 mm but if required it can be supplied even with 2 mm thickness. The higher thickness with high open area and rigid structure equip grid packing to handle severe operational surges without affecting its integrity. For applications that are prone to frequent operational upsets, the entire grid bed can be through bolted to function as a single integrated structure leading to enhanced mechanical strength.

GPAK comes in two different styles, namely GPAK #2 and GPAK #3 to meet individual application requirement. GPAK #2 employs saw-tooth blade resulting in reduced restriction to vapor flow and better washing by liquid resulting in higher fouling resistance and more capacity. GPAK #3 is equip with louver blade design to provide improved contact between up-flowing vapor and downflowing liquid giving high efficiency while ensuring higher capacity.

GPAK Grid structured packing are ideal choice for

- Wash beds within refinery vacuum columns and Coker & visbereaker fractionators

- FCC Fractionators Slurry Pa

- Olefin plant Oil fractionator and water quench column bottom section

Use of GPAK grid packing provides excellent resistance and improved de-entrainment performance in above applications leading to more reliable operation with extended run length, reducing operational cost and unplanned shutdown.