Random Packings Portfolio

Raschig rings were the first ever random packing introduced in the industry in 1915s. Since then several developments has taken place in random design to improve both capacity and efficiency. Having said that the two major shapes that makes bulk of modern random packing are ring type and saddle type. GLOBTECH provides an extensive variety of random packing type in various material including metallic and non-metallic type, (plastic, carbon and ceramic) to meet your process requirement.

Though structured packing are more common for packed bed design when it comes to maximizing capacity and minimizing pressure drop, there are several applications where random packing scores over structured packing in performance and or reliability. Some of these includes high pressure fractionators and or high liquid load systems. Random packing are preferred for corrosive services as they use higher thickness when compared to structured packing and also in fouling services due to ease of maintenance.

Within a given group or family of random the capacity and separation efficiency are directly linked to packing size and its specific surface area. As for structured packing, for random packing within the same family, higher the packing size higher will be the capacity. Having said that care must be taken to compare packing of same size from different families as geometrical shape and open structure of the packing media has significant influence on packing capacity and efficiency. For examples though 2” Raschig rings and CONPR #50 (equivalent to 2” Pall rings) are of same size (2”), CONPR #50 provide significant higher capacity and efficiency when compared to 2” Raschig rings.

Like structured packing, the efficiency of random packing within the same family is directly proportional to its specific surface area. Higher the surface area, higher will be the efficiency and vice-a-versa. However for random packing belonging to two different family, specific surface area in only one of the parameter that influence packing efficiency. This can be seen with modern random packing where by employing optimized geometrical shape and structure ensures higher utilization of surface area and improved liquid wettability giving higher efficiency per unit area of packing. For example though CONPR #50 and HPIR #50 has same specific surface area, HPIR #50 demonstrate typically 10% - 15% higher efficiency.

HPIR and HPCR High Performance packing uses optimized geometrical shape and structure to maximize effective use of packing surface area while providing minimum resistance to vapor and liquid flow across the column. This results in higher efficiency & capacity, reduced pressure drop and lower liquid hold-up. Both there packing have superior mechanical strength as they are equipped with integral flanges allowing deeper beds and less shrinkage when installed.

CONRR - Conventional RING Packing

- Traditional Random Packing with aspect ratio (diameter to height) of 1:1.

- Equivalent to Raschig rings random packing

CONPR - Conventional Random Packing

- Traditional Random Packing with aspect ratio (diameter to height) of 1:1.

- The cylindrical wall comes with multiple slots equip with inner fingers to minimize resistance to vapor flow and enhance liquid wettability of packing surface area leading to higher capacity and efficiency when compared to Raschig rings of same size.

- Equivalent to Pall rings random packing

HPIR - High Performance Random Packing

- Saddle shape structure with high open area giving low liquid hold-up leading to less vapor flow resistance. Improved packing surface area utilization due to enhanced lateral spreading of liquid.

- Optimum combination of capacity and efficiency for a given size of packing, providing 20%-25% higher capacity and 10%-15% higher efficiency along with 40% lower pressure drop when compared to CONPR of equivalent size.

- Lower liquid hold leads to less residence time and therefore lower fouling tendency. Peripheral flange provides higher mechanical strength that allows deep bed.

- Equivalent to IMTP® random packing

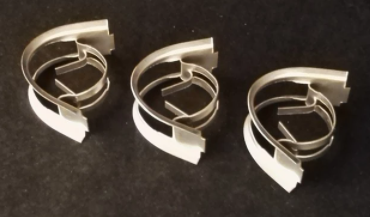

HPCR - High Performance Random Packing

- High performance random packing applies lower aspect (diameter to height) ratio of 1:3 when compared to conventional CONPR that uses 1:1. This results in preferential orientation of packing in near horizontal position when dumped in column

- The preferential orientation leads to lower resistance to vapor and liquid flow and more effective use of the packing surface area resulting in both higher capacity and efficiency when compared to traditional random packing such as pall rings.

- The preferential orientation also leads to less liquid hold-up providing improved fouling resistance.

- Higher mechanical strength that allows deeper beds.

- Equivalent to CMR® random packing