GTFRAC Tray Portfolio

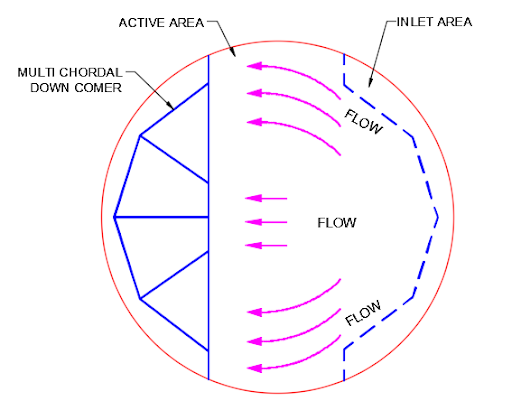

High Capacity trays use a combination of active area and inlet area enhancement with or without optimized downcomer design to maximize tray capacity for a given tray diameter, while giving same or higher efficiency when compared to conventional trays.

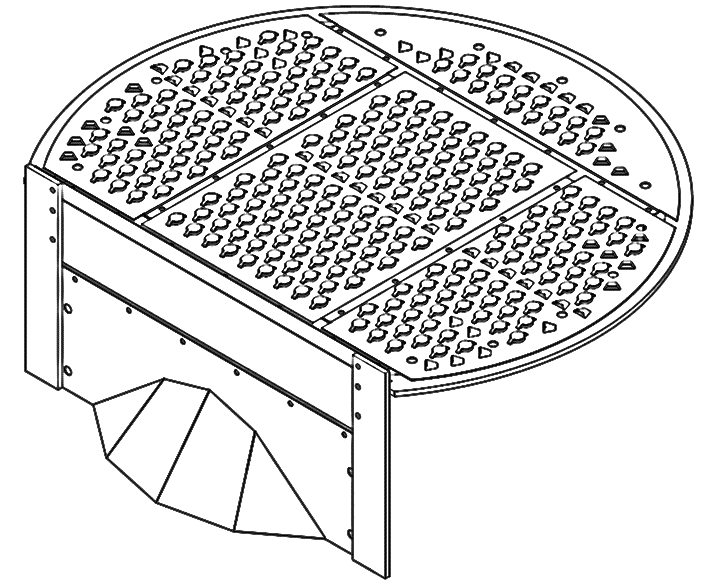

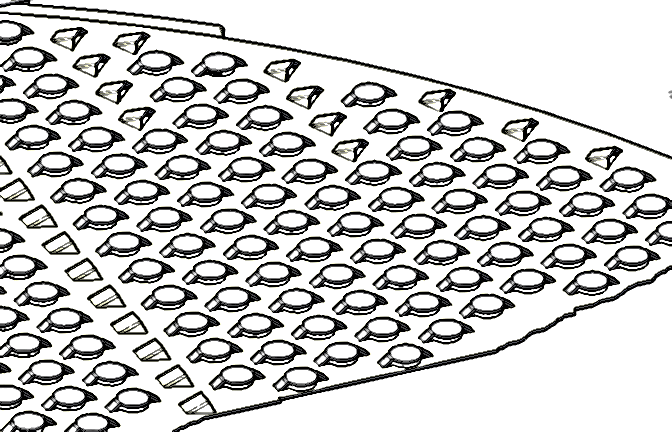

The active decks are equipped with FV0 fixed valves along with FPv directional valves in key locations ensuring uniform froth height across the entire tray cross section. The lower downcomer can be equipped with multi-chordal to maximize active area along with long flow path length. The design also employs our propriety SWIFT-FIT construction with bolt-less panel to panel joints that not only ensures quick installation (and removal) but also improved valve coverage. All these features allow GTFRAC High Capacity trays to provide 15% - 30% higher capacity when compared to conventional trays. Typical operating range is 1:2.5, while higher operating range up to 1:4 can be obtained by using RV0 valves in place of FV0 valves.

Benefits

- Even Froth Height

- Cross flow elimination

- Larger flow path length & AA

- Reduce Entrainment

- Lower Pressure Drop

- Anti Fouling Advantage

Design Features

- Liquid gradient elimination

- Plug flow using

- Optimized dc & active area

- Lateral vapor release

- Lower liquid crest

- Fixed valve with forward & lateral push