Globtech Engineers Services

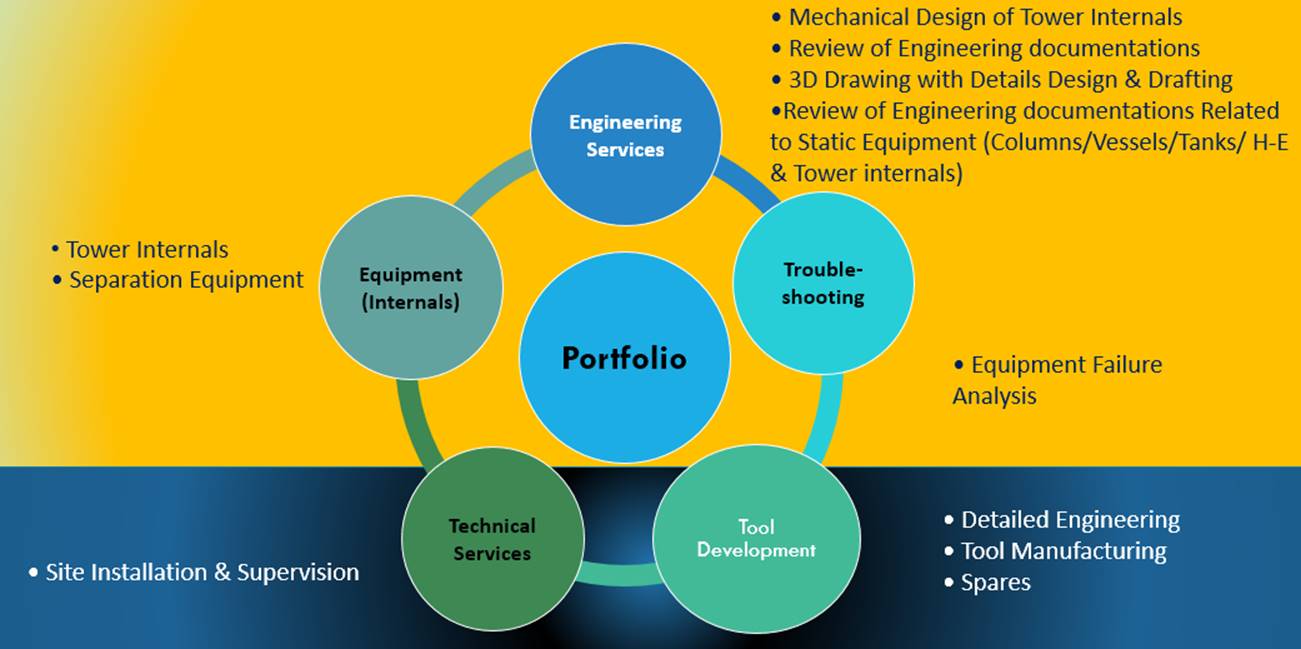

We offer complete solutions to our customer starting from basic design of tower internals till installation completion.

Technical Support

Technical drawing review for Pressure Vessels/Tanks/HE & Mass Transfer and Separation equipment satisfying all the process parameters provided by Vendor, EPC/PMC/End user and or Licensor. Review of each specification in line with Technical Bid Evaluation and MOM based KOM. Professional support for use of correct methodology or equipment based project specification, evaluation of vendors dwgs, to ensure compliance with licensor / PMC / Client specification. Able to draw leverage from 3 decades of professional experience and application knowledge to support client mass transfer and separation equipment requirement. We do support to co-ordinate with EPC/PMC/Licensor to explain and or resolve issues related to any of the technical problem related to Process and or Mechanical design from vendors side.

Design, Engineering

Our expertise is in Design & Engineering of Mass Transfer, Separation and Reactor Internals. Further we also offer support for design of static equipment including that for H/Ex, Tanks, Vessel, MDDS and Columns. Our team consists of highly qualified engineers with excellent product and application knowledge in Process & Mechanical design with average 25+ years experience. Our rich experience in this field with practical problem solving skills that we have gain from past projects help us to understand what has gone wrong in past which means of preventing similar incidents in the future. We are committed to deliver in-time solutions to our customer to meet all their targets and engineering needs. We work with our customer to maximize return on investment with innovative solutions for their any problems.

Shop & Field Services

Our professionals have wide experience for installation and supervision for Mass Transfer and separation products verification as per approved drawings. We do assist and support to inspect post fabrication inspection work to review tower internals supports to verify correctness of welded parts as per drawings. This process helps to avoid any uninvited problems at site while Tower Internal Installation. We do support to install and or supervision of Tray installation at Vessel vendor shop. Our key staff worked with over 500 + clients that includes big refineries in India and couple of them are located in ME & SA pacific.

Engineering Capabilities

- 3D mechanical design capability to develop complex revamp solutions

- Experienced engineering capability for large diameter column

- Engineering Solutions for horizontal installation

- Explosion Resistant Design (ex. Uplift design with or without explosion relief doors)

- Swift-Fit Joints construction for panel to panel joints, reducing installation time by 20%-25%

Turnaround replacement Services

- We are available 24/7, 365 days for inspection of existing and/or new equipment, supervise installation and provide expert advise on reuse of existing equipment or replacement to maintain column integrity

- Work with client’s T/A team before turn-around to identify equipment that may require replacement with a view to minimize inventory at client warehouse

- Provide like for like equipment to replace existing equipment including those of other OEMs

Static Equipment design

We offer advanced mechanical design engineering services to customer that help them in developing complex design and products. Our service portfolio includes comprehensive designing of pressure vessels, heat exchangers, process columns and reactors. We have built up an extensive knowledge of the major code including ASME VIII- 1, ASME VIII-2, TEMA, EN 13445 and have ability to supplement these where necessary with individual company and industry specific requirement. Let’s discuss and collaborate for your success.

Pressure vessel includes equipment like separator, deaerators, storage tank, reactors, air receiver etc. We have extensive knowledge of design of pressure vessel including;

- Design of pressure parts including nozzle, head, shell, support etc.

- Material selection

- Nozzle load design

- Wind and seismic calculation

- Optimized flange design

- Non pressure parts design including lifting lug, saddle and skirt support.

We also undertake mechanical design of all types of heat exchanger and have designed most configuration listed in TEMA. We have extensive knowledge on optimum design of critical components of shell and tube heat exchanger including tubes, expansion bellow and tubesheet.

Optimum mechanical design of process column requires extensive knowledge of material selection, stability criteria, deflection check, wind and seismic analysis and vortex shedding criteria check. Our team has in depth knowledge of column design engineering starting from basic, extended basic, detail engineering and erection of column at site. This helps client to provide cost effective and flawless execution.

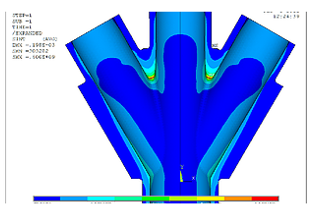

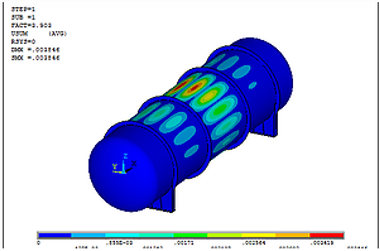

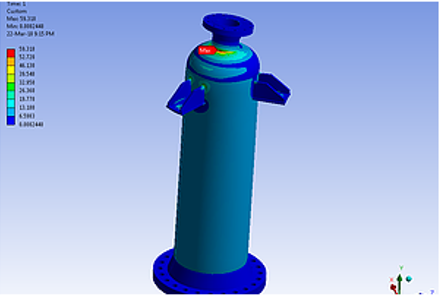

Finite element analysis

We have reach experience in carrying out finite element analysis across a wide range of engineering discipline fulfilling ASME, EN3445, ABSA and API 579 design by analysis requirement. Here are some of the most common cases where FEA is required to fulfill static equipment design.

- Local loads on process nozzles which are outside code limits

- Nozzle in the knuckle region

- Cone to cylinder junction

- Fitness for service assessment

- Fatigue analysis of cyclic service vessel

- Multiple support saddle analysis

- Floating tank roof

- Bolted flange connection

- Tank bucking analysis

- Consideration of nozzle loads on standard flange

We have performed several projects to perform FEA analysis to protect equipment against plastic collapse using commercial analysis software fulfilling ASME sec VIII and EN13445 requirement. Following are methods to evaluate protection against plastic collapse.

- Elastic Stress Analysis Method

- Limit-Load Method

- Elastic-Plastic Stress Analysis Method

Applicability of each method require engineering judgment to apply which method shall be best fit for the problems. For example, application of the limit load or elastic-plastic analysis is recommended for cases where the categorization process may produce ambiguous results. Also, use of elastic stress analysis combined with stress classification may produce non-conservative results for heavy-wall (where radius to thickness ration is less than 4) pressure containing components, especially around structural discontinuities and is not recommended.

In addition to demonstrating protection against plastic collapse, the applicable local failure criteria and protection against collapse from buckling shall be satisfied to avoid buckling of components with a compressive stress field under applied design loads. For that we have comprehensive analysis guideline to performed buckling analysis using commercially available software.

Following are areas where analysis of pressure equipment to protect against local failure and buckling is required.

- Buckling analysis for skirt/leg support vessel with large diameter to thickness ratio.

- Local stress analysis at cone to shell junction for tall columns

- Buckling analysis for rectangular vacuum vessels.

- Bucking analysis for vacuum vessel.

IFatigue, a major source of product failure, can sometimes result in significant damage and injuries. A fatigue evaluation shall be performed if the component is subject to cyclic operation. The evaluation for fatigue is made on the basis of the number of applied cycles of a stress or strain range at a point in the component. The allowable number of cycles should be adequate for the specified number of cycles as given in the User’s Design Specification. As code formulae’s are not available to determine fatigue stress, FEA is acceptable tool for performing fatigue analysis.

We have performed variety of project to perform fatigue screening as specified in div 2 para 5.5.2, and as per EN 13445 to determine fatigue analysis requirements for integral and non integral components of equipment. We also have performed series of projects using Elastic Stress Analysis and Equivalent Stresses and Elastic Analysis and Structural Stress approach with guideline provided in ASME div-2.

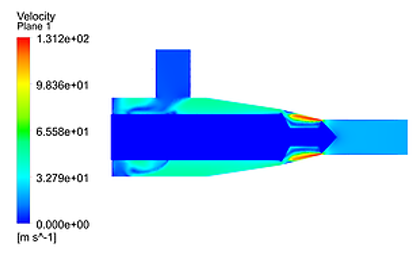

CFD analysis

We offer, Computational Fluid Dynamics (CFD) services to solve various analyses related challenges faced by industries during the product development. Our Approach to problem solving is starts with proper understanding of physics of the problem and preparing a right solution strategy. Benchmarking with available analytical or experimental data, validation of results is crucial part of CFD simulation process. We are committed to provide accurate and reliable results.

Heat transfer analysis is one of the areas, where CFD can be used to solve the problems involving conduction, convection, and radiation. It helps in calculating the heat transfer coefficients of various types of flows, including natural, forced, and mixed convection. Also, more complicated heat transfer effects like viscous heating, phase change, evaporation, cavitation, and boiling can be included.

Following are area where CFD become powerful tool to optimize design in EPC industries

- Temperature distribution evaluation

- Flow distribution under the packed towers using Vapor Distributors / Chimney Trays

- Flow simulation of burners and combustion chambers

- Analysis of mixing of fluids

- Heat transfer analysis of heat exchangers