Structured Packings Portfolio

SPAK - Conventional Structured Packings :

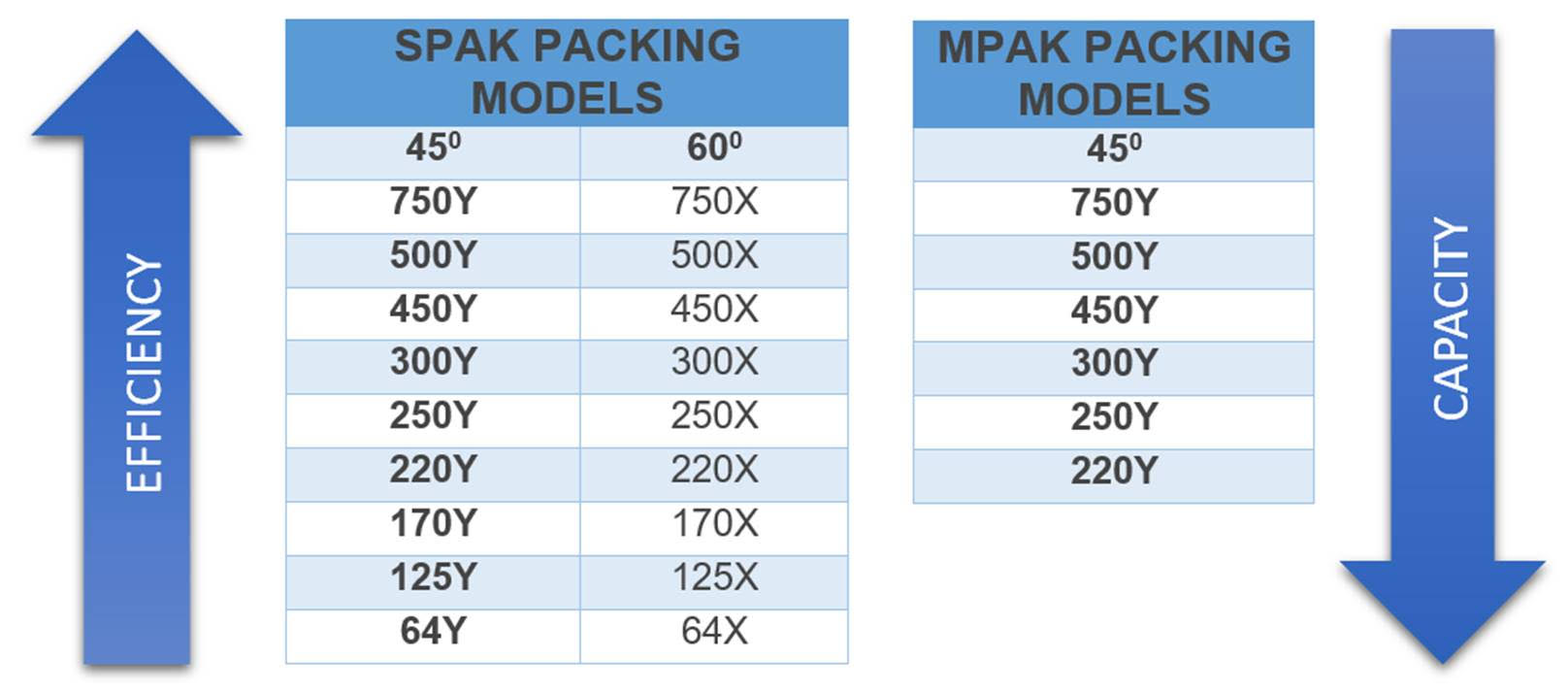

Conventional structured packing provides higher capacity and lower pressure drop when compared to random packing and trays due to less resistance to flow. By varying the crimp height we are able to provide our SPAK structured packing with specific surface area (SSA) ranging from 64 m2/m3 to 1000 m2/m3 to meet individual application requirement. Each of these packing comes in two different crimp angles namely "Y" type packing with a crimp angle of 45° (Y type) and "X" type (X type) with a crimp angle of 60°

"Y" type packing, that are more standard, provides higher stages per meter of packed bed height when compared "X" type of packing for same surface area and typically employed in fractionation services. "X" type of packing provides higher capacity and lower pressure drop when compared to "Y" type packing for same surface area and are typically applied in heat transfer and absorption services. It is also possible to use a combination of "Y" and "X" structured packing in a single bed to maximize both efficiency and capacity in some applications. The packing specific surface area has a direct relation to efficiency and inverse to capacity, in other words as the surface area of the packing is increased efficiency increases while its capacity decreases and vice-a-versa.

- Standard Models : SPAK-220 / SPAK-250 / SPAK-300 / SPAK-350 / SPAK-400 / SPAK-450 / SPAK-500 / SPAK-750 (“X” or “Y”)

- Available in both X (60º) and Y (45º) with Surface area from 60 m2/m3 to 750 m2/m3

Efficiency Vs Capacity by Product

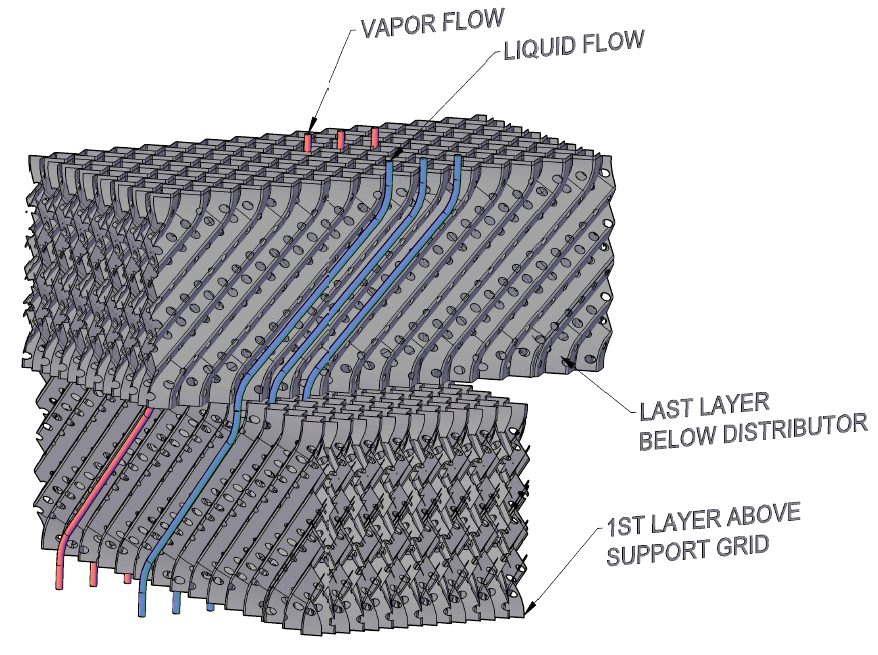

Typical Performance Sketch

MPAK - Enhanced Structured Packing :

The maximum resistance to fluid flow through packing channels is at the interphase of two packing layer limiting maximum usable capacity for standard structured for a given surface area. The directional change at the interphase of consecutive packing layer leads to additional resistance to vapor flow leading to liquid build-up causing additional pressure drop and consequently capacity loss. To overcome this limitation GLOBTECH has developed their MPAK High Capacity Structured Packing. With SPAK structured packing, the top and bottom portion of each layer employ a smooth transition to vertical axis allowing much lower resistance to vapor and liquid flow across the packed at the interphase. This modification equips MPACK additional 20%~30% more capacity and significant lower pressure drop when compared to conventional SPAK structured packing of same surface area.

MPAK packing can be used to revamped existing columns equipped with standard packing for higher capacity or can be applied in new columns to reduce column diameter. MPAK can also be an excellent revamp tool to increase existing column separation efficiency by replacing standard structured packing with MPAK resulting in additional separation stages with same and or additional capacity. For new column using MPAK in place of standard structured packing will result in smaller diameter and or shorter column resulting in lower CAPEX.

- Standard Models : MPAK-220 / MPAK-250 / MPAK-300 / MPAK-350 / MPAK- 400 / MPAK-450 / MPAK-500 / MPAK-750 (“Y”)

- This packing has 22%-28% higher capacity compared to conventional SPAK.

- Available in “Y” (45º) with Surface area from 220 m2/m3 to 750 m2/m3